Embodied AI

This area explores how artificial intelligence can be integrated into robotic systems, enabling robots to sense, act and learn to interact with the physical environment.

Advancing Safe Human-Robot Interaction

This project brings together advanced perception, natural language understanding, and real-time motion planning to make robots more aware of their surroundings and people around them. The goal: For robots to navigate with social awareness and safely in dynamic, human-centric environments like hospitals.

Domain-Specific Robotics Foundation Models for Manufacturing

We are developing robotics foundation models for faster and more reliable deployment of robotics in industrial environments. These models help robots manipulate different objects more effectively, collaborate safely with humans, and learn through real-world and synthetic data.

Assistive Robotics

This area focuses on assisting humans in rehabilitation, supporting independent mobility, and enhancing worker safety in industrial settings.

Mobile Robotic Balance Assistant (MRBA)

This wearable robot supports patients with balance disorders during rehabilitation by providing pelvic support. It has been trialled in multiple healthcare sites, and is on track for commercialisation through the project’s spinoff.

Wearable Robotics

Powered exoskeletons have been developed to help industrial workers reduce physical strain from manual tasks, lowering the risk of back injuries and improving workplace safety.

High-Fidelity Teleoperation

This technology allows users to control robots remotely with high precision and minimal delay. It is especially useful in harsh environments like cold-room operations, and high-risk scenarios like disaster response, where accuracy and safety are critical.

Materials for Robotics

This area covers enabling technologies that enhance robot performance in dynamic and unstructured environments, such as safe interaction with humans and handling of delicate or non-rigid items.

Soft Robotics Programme

This initiative led to the development of soft robotic grippers, which was spun off into a startup. These grippers are now used by companies like Philips and Coca-Cola for handling delicate or irregularly shaped items where flexibility and gentle touch are critical.

Tactile Sensors

Inspired by the sensitivity of human skin, these AI-driven, high-resolution electronic tactile sensors allow robots to detect and respond to touch. This enables them to grasp fragile objects with the right amount of force and safely interact with humans.

System Capabilities

This part of our work encourages multi-robot deployments through interoperability solutions, universal wireless charging devices, and reconfigurable and modular robots, especially in space constrained environments.

Robotics Middleware Framework (RMF/RoMi-H)

RMF enables robots from different companies to talk each other, coordinate tasks, and share infrastructure. It allows robots to take lifts, move across floors, and travel between buildings. RMF is currently used in hospitals and commercial buildings in Singapore. The underlying technology is available as a free, open-source system known as the Open Robotics Middleware Framework (Open-RMF), which supports modular development and wider adoption by the global robotics community.

Scalable Universal Wireless Charging Platform

This system provides a standard way for different brands and models of mobile robots to charge wirelessly. It reduces downtime, supports fast-paced operations, and requires less physical space as a single charging system can serve multiple vendors’ robots. Charging schedules can also be coordinated through RMF, making it ideal for environments like hospitals and logistics centres.

Reconfigurable and Modular Robotics - Inspection Robot

A modular inspection robot that has been deployed in false ceilings and sewage pipes. Its reconfigurable design makes it ideal for infrastructure inspection in tight spaces.

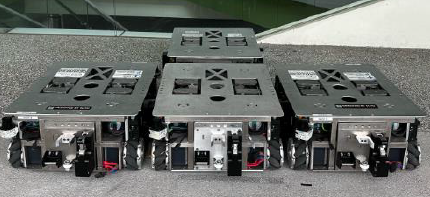

Reconfigurable and Modular Robotics - Mobile Platform

A modular robot platform designed for adaptability across changing environments and applications. Depending on the task, one or more units can be joined together to handle heavier loads or cover a larger area. Used in healthcare and logistics settings, it can be equipped with tools such as trays or robotic arms to support delivery, material handling, and patient monitoring, making it a versatile solution for dynamic operational needs.

Reconfigurable and Modular Robotics - Autonomous Pavement Sweeping Robot

An autonomous pavement sweeping robot equipped with AI-driven sensing and navigation to avoid obstacles while cleaning. Its dual sweeping system channels debris inward and lifts it into a bin for easy disposal.